Projects

Damatt Engineering, Inc. provides high-quality electrical and control systems engineering, programming, and design services for a wide variety of industrial clients. Our projects have included the design of new high-voltage substations, electrical distribution systems, medium-voltage motor and equipment protective relaying, and state–of-the-art process control systems.

Here is a sampling of our completed engineering, integration, and specialized projects:

INTEGRATION

Plant-wide Control System Modernization

Graniterock – Aromas, CA

Damatt provided engineering, PLC and HMI programming and commissioning services for the modernization of the existing control system at the quarry. The project was multi-faceted and performed over a five-year period and spanned between the primary, secondary, overburden, and loadout processes. Customized user defined data types, PLC code, HMI objects and graphics were created for the facility to standardize the operation at large. Ultimately, numerous PLC-5 programs were converted, 17 new processors were added, hardwired operations were converted to PLC control, a new communications infrastructure utilizing 12 miles of new fiber-optic cable was deployed, thousands of field and HMI data points were remapped or newly added, and 240 new HMI graphics were created and deployed.

Krupp Mobile Crusher Control System Upgrade

Graniterock – Aromas, CA

Regarded at one time as one of the largest mobile crushers in North America, Damatt was brought in to manage the integration of a new hydraulic pump unit as well as the engineering and integration of a new control system. The control system was used to provide advanced protection of the crusher, startup of the supporting hydraulic pump units, lubrication units, and conveyors. Ethernet based encoders were deployed per wheel to work in concert with a new steering scheme based on engineered moves. In total, 20 PID and hysteresis control loops were deployed to manage the steering operation.

Aggregates Plant Modernization

Lehigh Hanson – Clayton, CA

Damatt provided electrical and automation design services for a complete update of an existing aggregates facility. The project required working closely with an interdisciplinary engineering team to provide a new crushing, screening, and sorting facility that will run efficiently for decades to come. Detailed electrical equipment procurement specifications along with a detailed set of construction drawings that will serve as an accurate reference for maintenance personnel were developed. Damatt’s automation team developed a modern PLC system with robust equipment sequencing and a visual interface that effectively communicates the plant’s running status to the operator at a glance. Damatt completed construction observation activities and supplied commissioning and start-up support services.

Material Recovery Plant and Shredder

SA Recycling – Bakersfield, CA

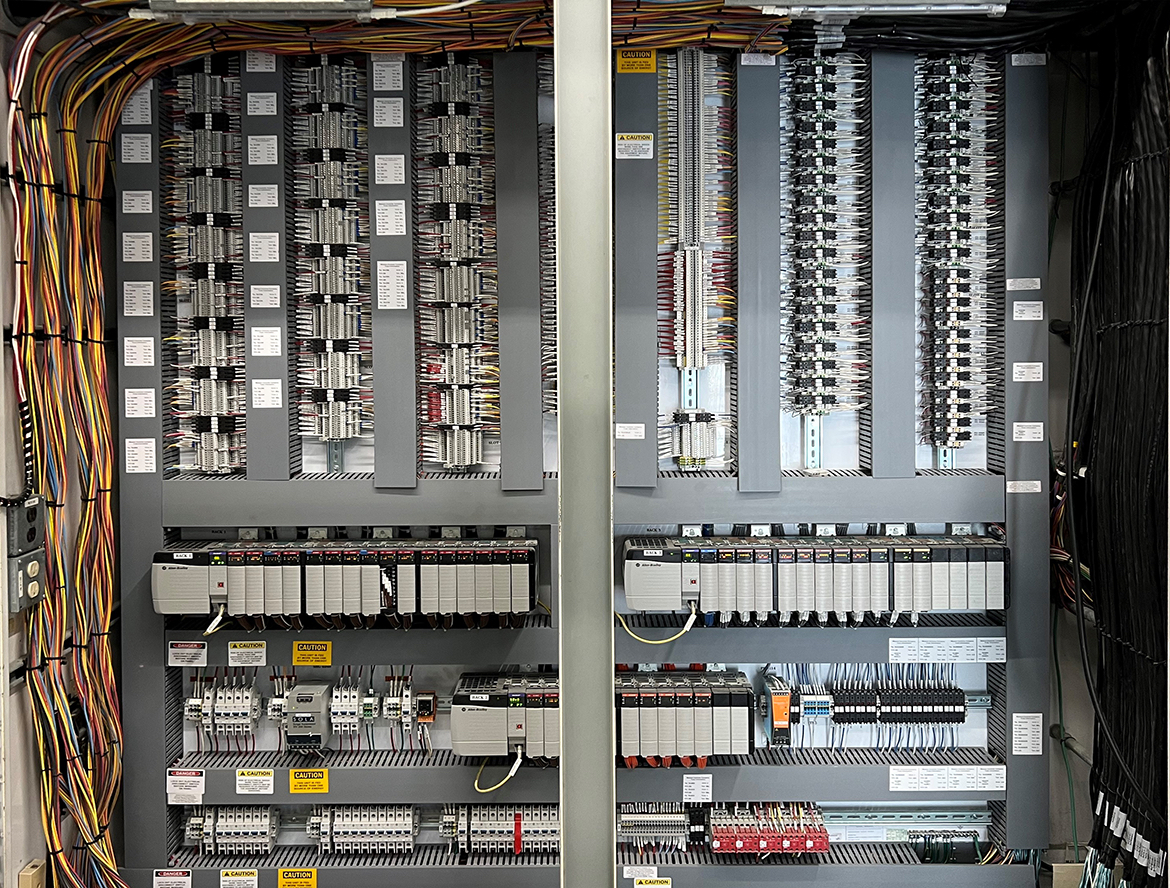

One of the most complete examples of our integration capabilities, this installation encompassed all project-related services provided by Damatt Engineering. Damatt provided complete engineering services related to the electrical power and control system design for the installation of a new shredder along with a material recovery plant. This entailed providing the design, engineering, construction support, and start-up services for a 69/4.16 kV 20 MVA industrial substation with protection relaying, 6000 HP medium-voltage motor protection relaying, multi-building electrical distribution, and motor control centers. The project involved the design of multiple control panels, each utilizing Allen-Bradley PLC/PAC components. A server was deployed along with numerous HMI’s and Ethernet switches on a fiber-optic and CAT 6 copper backbone allowing plant-wide control system communication. All PLCs, PACs and HMIs were programmed and integrated in a seamless fashion to allow supervisory control and data acquisition. Data is continuously logged to a database for management interaction.

9000 HP Shredder

Schnitzer Steel Products – Oakland, CA

Initially brought in to assist with construction permitting, Damatt helped complete the electrical design for a new 115kV Switchyard to provide power for a new 9000 HP Shredder and auxiliary equipment. The project included a main 14MVA transformer to power the Shredder and a 7.5 MVA auxiliary transformer to power the remainder of the site. The project required coordination with PG&E and the Port of Oakland for power delivery to the new Switchyard. Although similar in nature to other shredder plants previously worked on, the challenge presented here was that this was not an entirely new installation, but one that required a considerable amount of remodeling of both the mechanical and electrical systems. The installation was performed using a phased approach to keep the old shredder running until the final cutover could take place. This phased installation included the re-design of switchgears, motor control centers, the addition of new control panels and control networks. All PLCs, PACs and HMIs were programmed and integrated in a seamless fashion to allow supervisory control and data acquisition.